Manufacturing Base (Domestic)

Manufacturing Base (Domestic)

Manufacturing Base (Overseas)

Manufacturing Base (Domestic)

Kurakake Plant

- Main production items

- Reserve tank

Urea water tank

Rubber injection molding: air intake hose - Rubber product manufacturing equipment

- Pressure kneader 2 units

Mixing roll 2 units

Rubber cutting machine 1 unit

Complete weighing system 1 unit

200ton rubber injection molding machine 3 units - Plastic product manufacturing equipment

-

Hot plate melting machine 20 units

Leak inspection machine 9 units

Assembly machine 10 units

Press forming machine 1 unit

Slitting machine 1 unit

Honing machine 2 units

Band saw 1 unit

Cutting machine 1 unit

ISO9001, ISO14001 certified

Kurakake Plant

・April 2004 ISO 9001 certified

・July 2007 ISO14001 certified

Kurakake Plant

・November 2018 ISO 9001 certified

・November 2018 ISO14001 certified

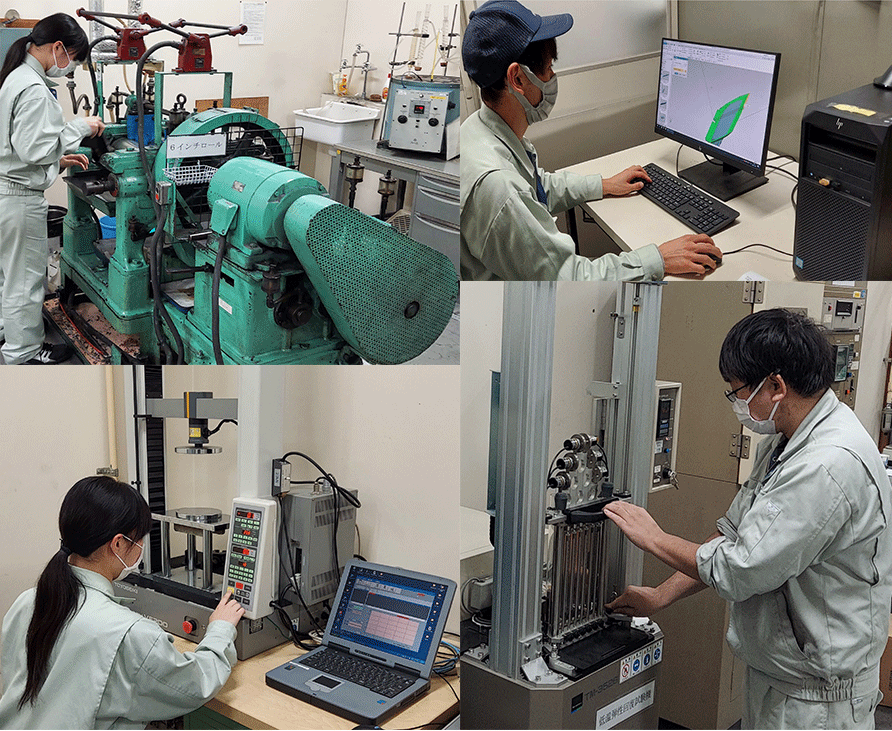

The Technical Center

At Mitoyo, we supply rubber products using our self-developed rubber formulations to various industries, including the automotive industry.

Our Technical Center conducts research and development, improvement, quality checks for rubber materials used in our own and cooperative factories, and performance evaluations of our products.

Furthermore, we are accumulating knowledge on molding and processing of plastic products to meet the needs of our customers.

Welding and assembly of plastic products

The process of manufacturing plastic products, including welding, leak testing, and final inspection, from small reserve tanks to large urea solution tanks, is carried out on a compact production line with a small number of workers.

-

- address

- 4119-2 akahori, oura, oura, Gunma, 370-0614

-

- TEL

- 0276-70-2777

-

- FAX

- 0276-70-2830

Kumagaya Plant

- Main products

- Hose & pipe for air conditioner

- Main equipment (Pipe Line)

-

Terminal processing machine & rolling machine 2 units

High-frequency brazing 1 unit

Robot bendor 2 units

Helium leak tester 1 unit - Main equipment (Hose Line)

-

Pipe cutter 3 units

Nipple processing machine 4 units

Terminal processing machine & rolling machine 7 units

NC bendor 10 units

Robot bendor 4 units

Brazing 10 units

Heat treat furnace 1 unit

Hose caulking machine 9 units

Water leak tester 4 units

ISO9001 certified

December 2003 ISO 9001 certified

The feature of our Hose & Pipe’s Processing, Welding and Assembly

In our production line, aluminum pipe’s terminal processing, bending etc. are automated. In addition to that depend on the requested applications, utilize most adequate processing technologies such as hose caulking, brazing, etc. and regarded as a mother factory of high- & low-pressure hose & pipe.

Capability to apply for high-mix and low-volume production

In our plant, jigs and tooling for manufacturing are in-house design and production. Accordingly, we have capability to apply even high-mix and low-volume production products. Also we have been manufacturing parts for various types of vehicles, such as passenger cars, trucks, construction machinery, and EVs.

-

- address

- 370-1 sendai, kumagaya, Saitama, 360-0107

-

- TEL

- 048-536-6911

-

- FAX

- 048-536-6910

Kyushu Plant

- Main products

-

Reserve tank

Air cleaner

Sound creator

Plastic molded products: Fuel Lids, Canister

Hose & pipe for car air conditioner - Main equipment (Plastic Molding)

-

230ton Plastics Injection molding machine 1 unit

75ton Plastics vertical Injection molding machine 1 unit

Vibration welding machine 1 unit

Mold temperature controller 6 units

Hot air dryer 1 unit

Dehumidifier dryer 1 unit

Hot plate welding machine 4 units

Leak tester 2 units

Band saw 3 units

High speed cutter 1 unit

Drilling machine 3 units

Thermostatic bath 1 unit - Main equipment (Hose & Pipe)

-

Pipe cutter 2 units

Nipple processing machine 2 units

Terminal processing machine & rolling machine 4 units

Brazing machine 5 units

Robot bendor 5 units

Helium leak tester 2 units

ISO9001 certified

Plastics Molding

・April 2007 ISO 9001 certified

Hose & Pipe

・January 2018 ISO 9001 certified

Plastic molding, welding and assembly line

Kyushu Plant plastic factory has Molding machines as well as machines for post molding secondary processing, such as for vibration welding, hot plate welding in order to meet various customer needs.

Hoses & pipes

The Kyushu Factory (Hoses & Pipes) is operating with the latest equipment designed for efficient production line.

75ton Vertical plastic injection molding machine

This machine is actively used as a vertical molding machine for insert molding of elastomers.

-

- address

- 〒825-0001

1824-17 ikari, tagawa, Fukuoka, 825-0001

-

- TEL

- 0947-46-5003

-

- FAX

- 0947-46-5004